novo.lign

-

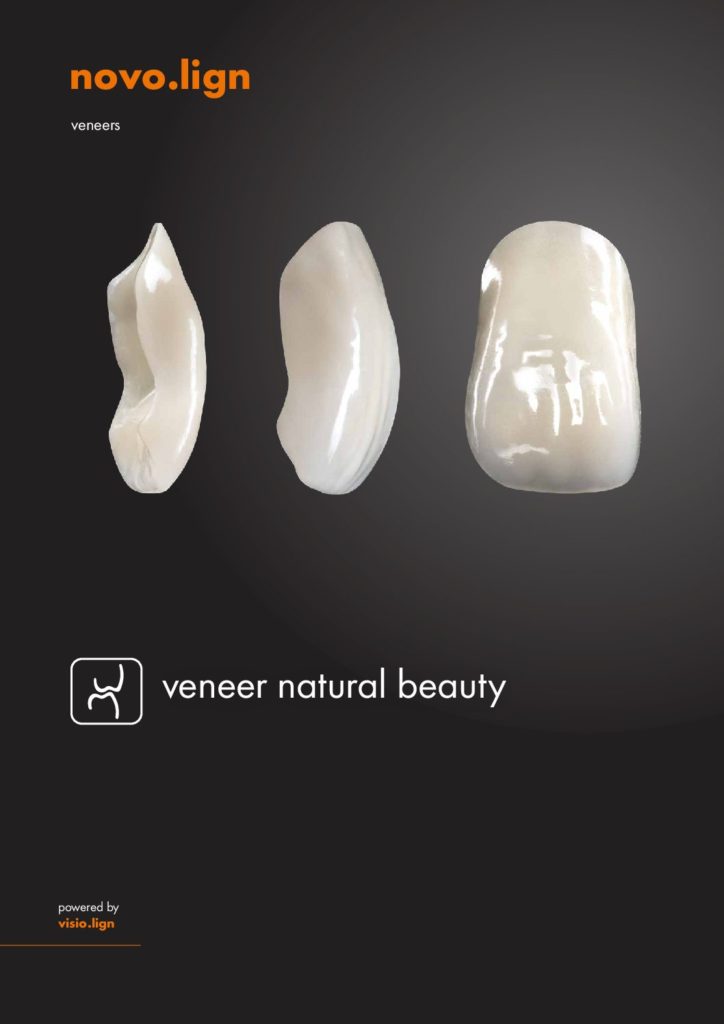

Natural beauty

natural designs and effect of depth – can be perfectly combined with neo.lign teeth

Simple handling

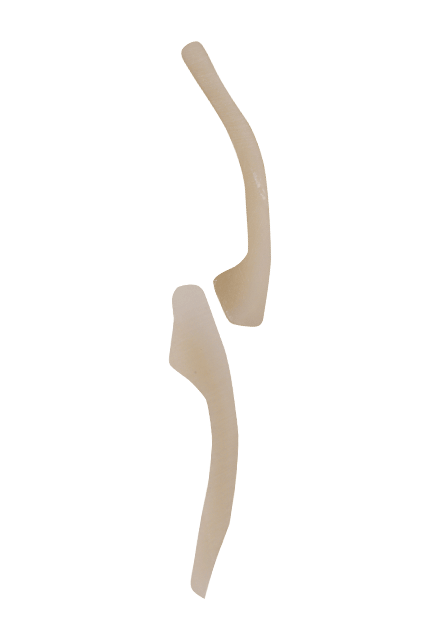

extended necks, can be thermoformed and individualised with crea.lign

Reliability

proven system – more than 10 million veneers insertedThe novo.lign veneers consist of high impact polymer composite filled with microceramic, and can be used for the permanent veneering of metal, ceramic and polymer frameworks.

They are moulded from real rows of teeth and, therefore, give a perfect natural look. The morphological layer structure also ensures the veneer has a natural depth.

Thanks to its exceptional mechanical properties, such as its high flexural strength (140 MPa) and low modulus of elasticity (approx. 3,000 MPa), the physiological veneers have a shock-absorbing effect and are, therefore, perfect for implant prosthetics. The homogeneous and sealed surface ensures long-term colour stability and plaque resistance. Because they have the same shades and shapes, they can be seamlessly combined with neo.lign denture teeth.

-

-

Natural beauty

• Natural design, because every novo.lign veneer is moulded from real rows of teeth

• Natural depth effect thanks to the morphological layer structure

• Same shades and shapes as the neo.lign denture teeth

• Homogeneous and sealed surface ensures long-term colour stability and plaque resistance -

Simple handling

• Extended neck enabling individual setting of tooth length

• Can be thermoformed, and therefore adapted to any situation

• novo.lign veneers can be seamlessly combined with neo.lign denture teeth, and are therefore perfect for the combination technique and for implant prosthetics (same shades and shape)

• Can be be individualised with crea.lign veneering composite -

Reliability

Veneer with a high load-bearing capacity

• Highly stable bond:

The best bonds between novo.lign veneers and framework materials are achieved using the bond.lign primer/bonder (see the Voss shear test conducted by the University of Jena on page 12/13 of novo.lign brochure Ref.009939GB).

• High-strength, fracture-proof & abrasion-resistant:

Thanks to its high impact polymer structure and high flexural strength of approx. 140 MPa, the novo.lign veneers are very strong and fracture-proof. The ceramic filler structure also increases its resistance to abrasion.

• No spalling or cracks thanks to the similar modulus of elasticity of the interacting novo.lign, BioHPP, combo.lign and crea.lign products.

• Proven system: More than 10 million veneers inserted -

Intraoral application

• Perfect for implant prosthetics

novo.lign’s low modulus of elasticity (approx. 3,000 MPa) ensures that the implant has a shock-absorbing effect.

The interaction of the similar moduli of elasticity of BioHPP (approx. 4,500 – 5,000 MPa), novo.lign (approx. 3,000 MPa), combo.lign (9,000 MPa) and crea.lign (5,000 MPa) also support the implant’s shock absorbing effect and make the whole restoration high physiological.

• Natural feel in the mouth

thanks to the neutral flavour and neutral behaviour in contact with cold and hot food. No chattering of teeth. Does not feel like a foreign object in the mouth.

• Biocompatible

Barely any residual monomer as the veneer is completely polymerised at 250 bar and 120 °C.

• Protection of antagonists,

as no dental glass is used in the material.

-

-

-

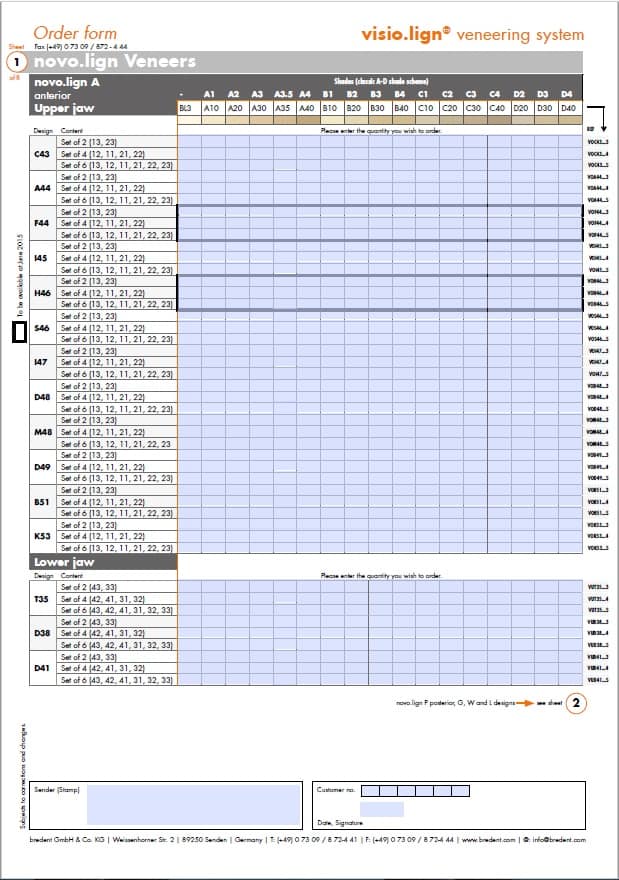

novo.lign A – 15 anterior shapes

All available anterior shapes can be seen in “Range of designs” brochure

All available anterior shapes can be seen in “Range of designs” brochure

Buccal wall thickness 1.0 mm

• 12 upper moulds

• 3 lower moulds

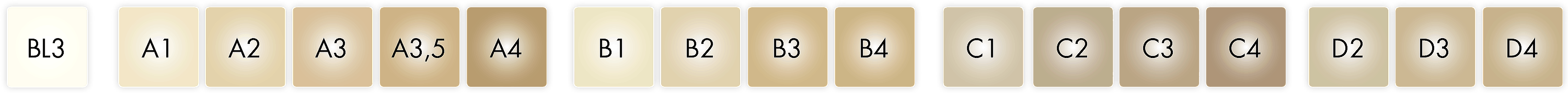

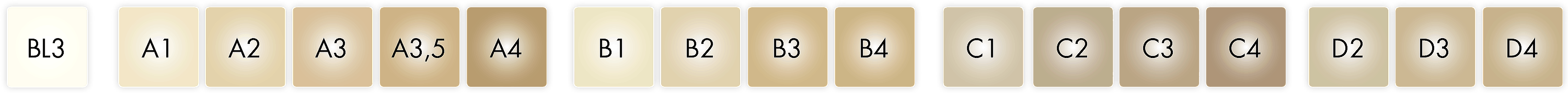

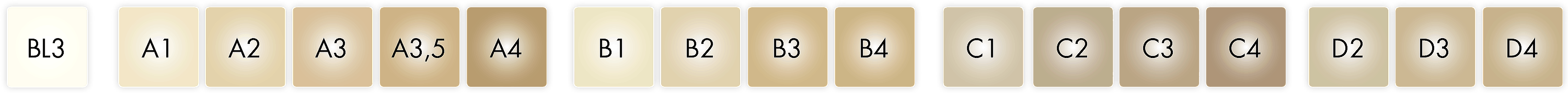

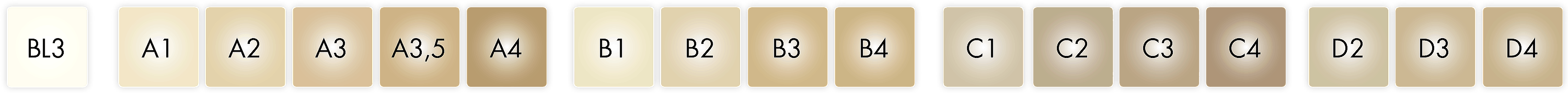

Available shades

Order form is available for download

Order form is available for download

-

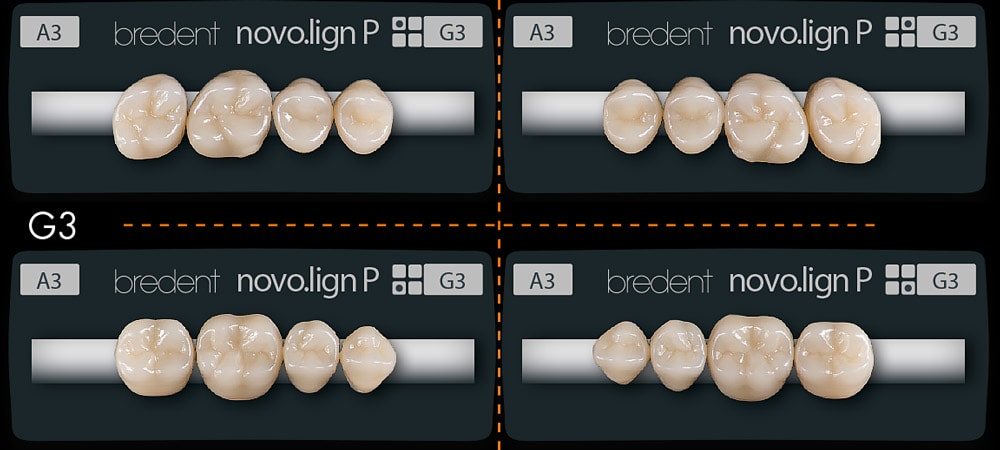

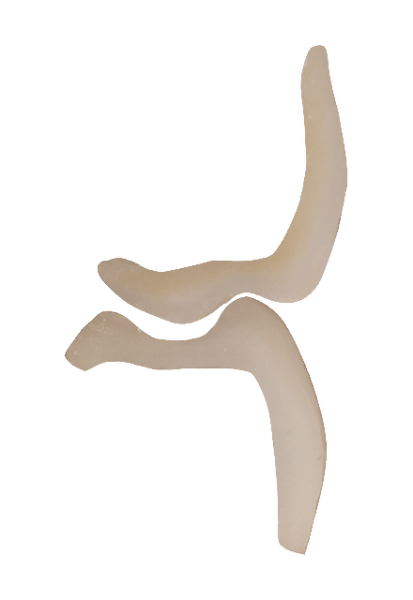

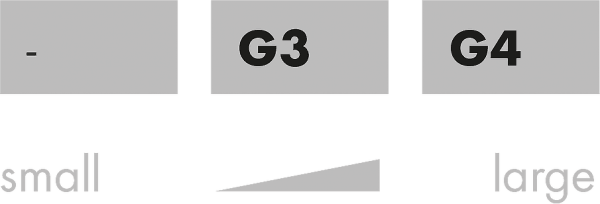

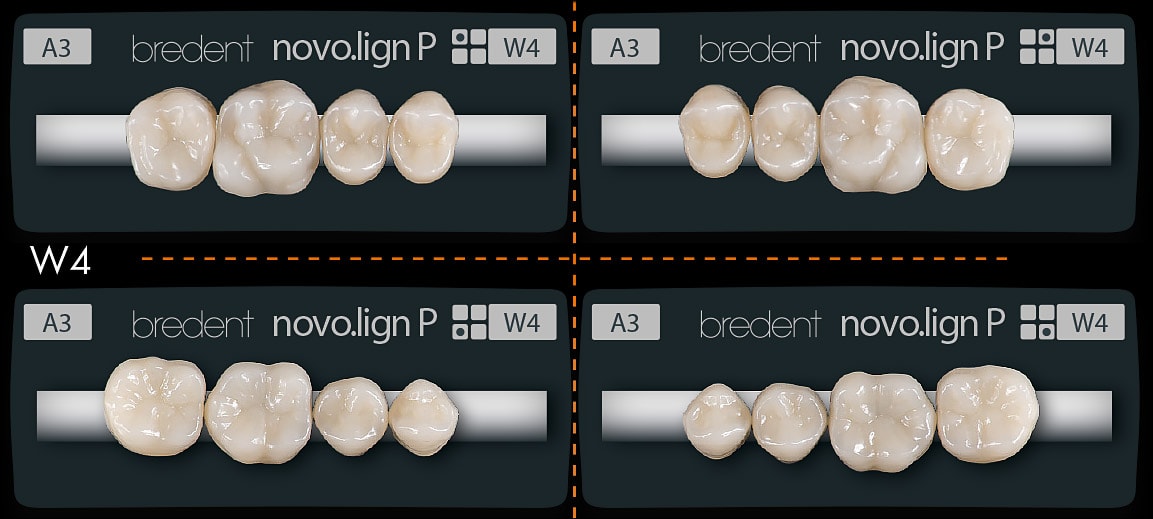

novo.lign P

G designs – 2 posterior shapes

All available posterior shapes of G design can be seen in”Range of designs” brochure

All available posterior shapes of G design can be seen in”Range of designs” brochure

Buccal wall thickness 1.2 mm

• Multi-functional occlusal design

for all occlusion concepts

Available in sizes

Available shades

Order form is available for download

Order form is available for download

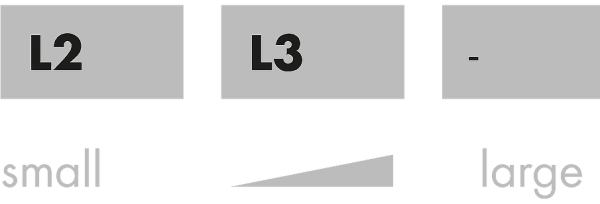

L designs – 2 posterior shapes

All available posterior shapes of L design can be seen in “Range of designs” brochure

All available posterior shapes of L design can be seen in “Range of designs” brochure

Buccal wall thickness 1.0 mm

• lingualised occlusal design for full dentures

Available in sizes

Available shades

Order form is available for download

Order form is available for download

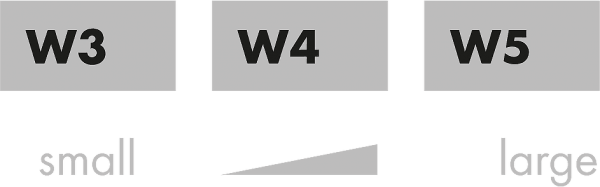

W designs – 3 posterior shapes

All available posterior shapes of W design can be seen in “Range of designs” brochure

All available posterior shapes of W design can be seen in “Range of designs” brochure

Buccal wall thickness 0.8 mm

• Multi-functional occlusal design for all occlusion concepts

• Extra-wide tooth design, particularly recommended for veneering crowns and bridges

Available in sizes

Available shades

Order form is available for download

Order form is available for download

-

novo.lign A&P sets content

-

Clearly legible display

Spacious drawer

The focus in the development was on ease of use and a particularly large capacity. The drawer easily accommodates large-size objects, such as flasks.

Using the benefits of the entire relevant spectrum of light

Experience a new level of reliability and speed when polymerizing your objects. The innovative and new LED technology of bre.Lux 2 covers the entire relevant spectrum of light below 400 nm and hence enables a new quality of polymerization. It offers the user more consistent and faster curing since different wavelengths can reach different depths. Increase your reliability and reduce your polymerization times.

Rotary plate and Light-Tray

Convenient, activatable, removable – this rotary plate guarantees that the object is evenly illuminated by the 72 LED lights from all sides. As a transparent tray, the Light-Tray transports light to areas that are otherwise inaccessible. Expose the objects to pure light!

Outstanding power

72 LED lamps will give you unsurpassed and highly efficient luminous power to prevent shrinkage in a clever way. Moreover, temperature control of 45°C – 55°C eliminates thermal influences such as overheating and embrittlement of the object. Additionally, the fan is extremely silent.

12 years (20,000 hours) at your service

In a highly efficient manner, the 72 LED lights of bre.Lux 2 transform the power input into light energy and offer a longer service life than halogen lights (max. service life of 2,000 hours).

-

bre.LUX LED N2 hand lamp

bre.LUX LightPen

The bre.Lux LightPen is a cordless angled hand light. It has a wavelength spectrum of 385 – 515 nm and can be used for any type of photoactive material. The device is used for rapid curing of composites such as crea. lign and light-curing die varnishes or for fixing veneers with the combo.lign luting composite. The bre.Lux LightPen offers four individually selectable time intervals – 5, 10, 15 and 20 seconds. The time interval last selected is automatically used for subsequent polymerisation cycles. The bre.Lux LightPen light guide can be rotated continuously through 360°, thus offering optimum comfort in extraoral use. The breLux LightPen does not replace final polymerisation in a polymerisation device. The bre.Lux LightPen, including adapter, charging cradle and orange glare shield, is available separately or in a set with the bre. Lux PowerUnit 2 light polymerisation device.

bre.LUX LightPen Set: Angled hand light + Anti-glare shield (orange) + Adapter + Charging cradle (Ref. 14002024)

-

Thermo-Pen

Hot air blower with piezo technique

The Thermo-Pen works without an open flame and can feed hot air up to 250 °C into the veneer interior.

-

-

-

The aesthetic fitting enables the patient to see the results in their mouth in advance. I think this is the most important advantage of veneers compared to other veneering materials. The aesthetic fitting helps me and the dentist advise patients, it is therefore a vital factor in our communication with our patients. The novo.lign veneers offer me a reproducible aesthetic. It doesn’t matter which member of the laboratory team processes the novo.lign veneers, I always get a top-quality aesthetic result. This gives me certainty and makes my laboratory even more efficient.

The aesthetic fitting enables the patient to see the results in their mouth in advance. I think this is the most important advantage of veneers compared to other veneering materials. The aesthetic fitting helps me and the dentist advise patients, it is therefore a vital factor in our communication with our patients. The novo.lign veneers offer me a reproducible aesthetic. It doesn’t matter which member of the laboratory team processes the novo.lign veneers, I always get a top-quality aesthetic result. This gives me certainty and makes my laboratory even more efficient.

Sebastian Schuldes, Dental Technician, M.Sc.

-

I have been successfully working with novo.lign veneers and neo.lign denture teeth since 2007. The system consisting of novo.lign, the corresponding bonding composite and the corresponding primer/bonder doesn’t just help me achieve a high aesthetic level, it also ensures the long-term success of the restoration due to its high plaque-resistance and low staining susceptibility. For combination work and implant prosthetics, the combination of novo.lign and neo.lign is the perfect solution for me.

I have been successfully working with novo.lign veneers and neo.lign denture teeth since 2007. The system consisting of novo.lign, the corresponding bonding composite and the corresponding primer/bonder doesn’t just help me achieve a high aesthetic level, it also ensures the long-term success of the restoration due to its high plaque-resistance and low staining susceptibility. For combination work and implant prosthetics, the combination of novo.lign and neo.lign is the perfect solution for me.

Antonio Lazetera, Dental Technician

-

-

-

REF 000224GB

REF 000569GB

REF 009504GB

REF 000234GB

REF 009939GB

REF 000202GB

-